Advanced analytics uses AI, machine learning, and big data to make demand forecasting more accurate, responsive, and resilient.

Key benefits include improved forecast accuracy, reduced inventory costs, faster decision-making, and better collaboration across departments.

AI enables real-time demand sensing, automated anomaly detection, and dynamic “what-if” planning.

eZintegrations™ provides seamless data pipelines and prebuilt API connectors, while Goldfinch AI enhances predictions with unstructured data and intelligent modeling.

Future-ready enterprises are using these tools to outpace disruptions and unlock strategic planning agility.

In today’s fast-paced, multi-channel business landscape, traditional demand planning methods fall short. Fluctuating customer expectations, global supply chain disruptions, and data silos all make it difficult to predict demand accurately. According to a 2024 McKinsey report, 73% of supply chain leaders say they struggle with forecast accuracy due to fragmented data and reactive planning processes.

That’s where advanced analytics comes into play combining AI, machine learning, and big data to provide deeper insights, faster decisions, and more accurate forecasts. In fact, companies using AI-driven demand planning have reported a 20–30% reduction in inventory costs and up to a 65% improvement in forecast accuracy, according to Gartner and BCG studies.

Modern enterprises are now integrating AI-powered demand planning tools that help reduce forecasting errors by up to 50%, improve service levels, and decrease excess inventory. The global demand planning software market is projected to grow at a CAGR of 10.5%, reaching $10.6 billion by 2029, underscoring its rising importance.

In this blog, we’ll explore how advanced analytics is transforming demand planning, including key technologies, use cases, and best practices.

Demand planning is the process of forecasting future customer demand for a product or service to ensure that a business can deliver efficiently and profitably. It combines historical sales data, market trends, seasonal patterns, and predictive models to estimate future demand as accurately as possible.

This process sits at the core of supply chain management and impacts inventory levels, production scheduling, staffing, procurement, and financial planning. Effective demand planning helps organizations align supply with actual demand, avoiding both overstock and stockouts.

Modern demand planning goes beyond spreadsheets and intuition it now integrates AI, real-time data, and external signals (such as weather, economic indicators, or social media buzz) to continuously refine forecasts and adapt to change.

Data Collection: Aggregates historical sales, inventory, and market data.

Forecasting Models: Uses statistical or AI-based methods to predict future demand.

Collaboration: Involves stakeholders across sales, marketing, finance, and operations.

Scenario Planning: Runs simulations to prepare for uncertainties or disruptions.

Continuous Monitoring: Adjusts forecasts in real time as new data emerges.

Demand planning is mission-critical for any organization managing inventory, production, or logistics. Poor planning can lead to excess inventory, lost sales, poor customer experience, and financial inefficiencies.

In today’s volatile and digitally connected world, where customer preferences shift rapidly and supply chains are complex, accurate demand planning can be the difference between profit and loss.

Reduces Inventory Waste: Minimizes overproduction, markdowns, and storage costs.

Improves Customer Satisfaction: Ensures product availability and on-time delivery.

Boosts Operational Efficiency: Aligns production, staffing, and procurement with actual need.

Enables Agile Supply Chains: Adapts quickly to market changes, seasonal shifts, and disruptions.

Informs Strategic Decisions: Supports accurate budgeting, marketing campaigns, and product launches.

Enhances Collaboration: Encourages alignment across departments to plan smarter together.

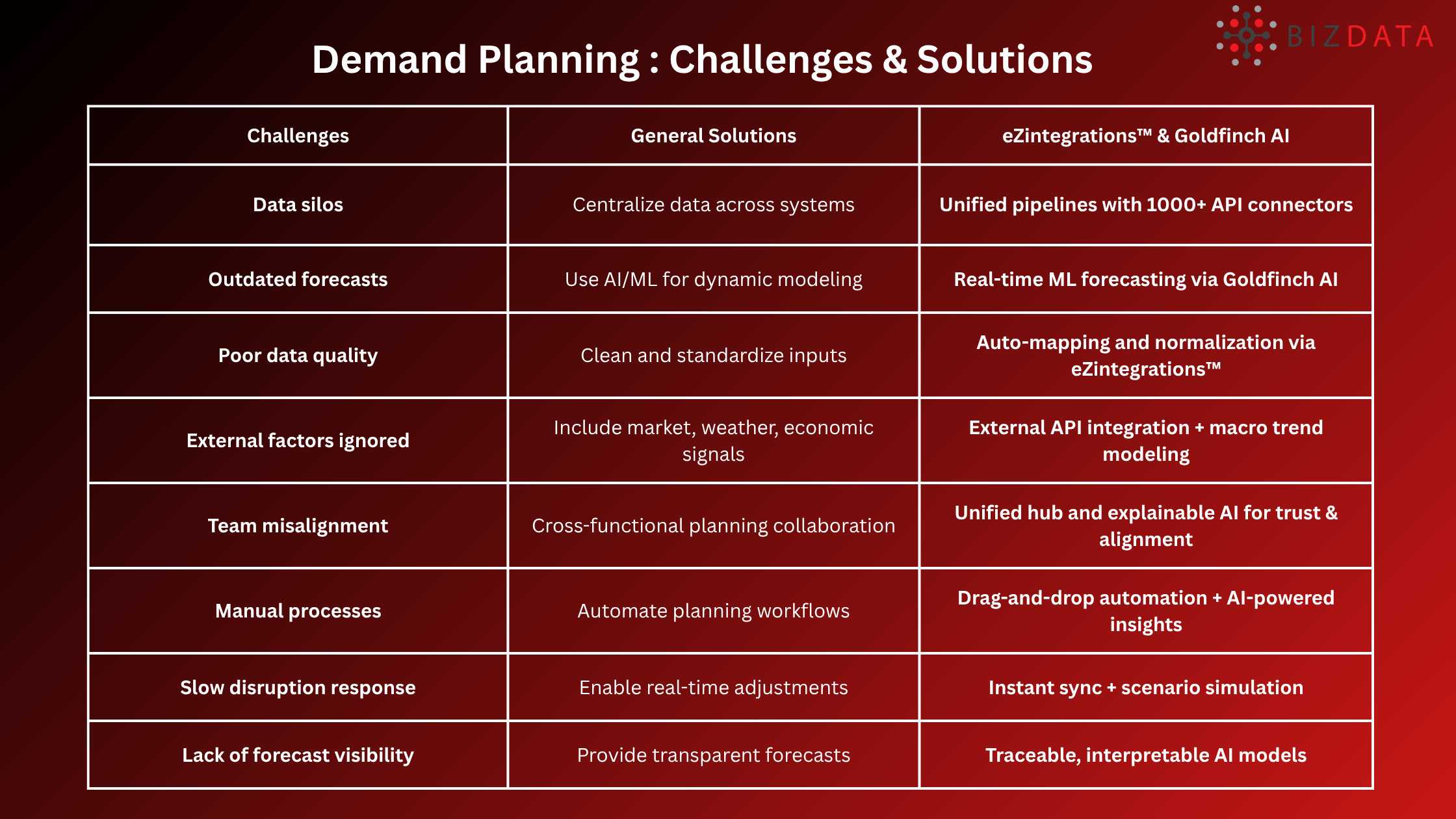

Demand planning is vital, but executing it effectively is complex. Businesses face numerous challenges that hinder accurate forecasting and responsive planning. Below are key obstacles that impact demand planning performance:

Issue Summary: Forecasts suffer when data is scattered across disconnected systems.

Without unified data from ERP, CRM, sales, and inventory platforms, teams struggle to build a real-time, accurate demand picture.

Issue Summary: Traditional, static models can’t adapt to today’s market volatility.

They fail to account for sudden changes like supply disruptions, economic shifts, or customer behavior patterns.

Issue Summary: Inconsistent or missing data leads to unreliable forecasts.

Forecasting accuracy drops when data is duplicated, outdated, or unstructured.

Issue Summary: Internal data alone doesn’t reflect actual market dynamics.

Ignoring key signals like weather, competitor activity, or economic indicators restricts planning effectiveness.

Issue Summary: Sales, marketing, and operations often plan in isolation.

Misalignment between teams leads to conflicting inputs and inaccurate demand projections.

Issue Summary: Outdated tools slow down decision-making.

Spreadsheet-based planning is error-prone and doesn’t scale with product or market complexity.

Issue Summary: Static forecasts can’t adapt in real time.

Unexpected changes in demand or supply require immediate scenario planning something many teams lack.

Issue Summary: Black-box models reduce trust and usability.

Without visibility into what drives forecasts, planners hesitate to act on insights.

Advanced analytics in demand planning refers to the use of sophisticated data science techniques like machine learning, predictive modeling, and real-time data ingestion to improve forecasting accuracy and responsiveness.

It goes beyond simple historical analysis by incorporating:

External data signals (market trends, weather, social media)

Real-time sales and supply chain data

Dynamic modeling techniques for continuous forecast adjustment

Unlike traditional forecasting models that rely on static spreadsheets and seasonal assumptions, advanced analytics provides probabilistic, scenario-based insights that help businesses proactively plan for uncertainty.

Organizations that adopt advanced analytics into their demand planning workflows see measurable gains across operations, finance, and customer service. Here’s how:

Improved Forecast Accuracy: ML models can reduce forecast errors by up to 30–50% by continuously learning from data patterns.

Agility in Planning: Simulations and “what-if” scenarios help teams plan for multiple outcomes and respond quickly.

Reduced Inventory Costs: Better demand prediction avoids overstocking or understocking, optimizing working capital.

Enhanced Customer Experience: Accurate planning improves service levels and on-time delivery rates.

Collaborative Decision-Making: Unified data views enable sales, marketing, and operations to plan together.

AI is a game-changer for demand planning. Its ability to analyze massive volumes of structured and unstructured data in real time enables the following:

Automated Forecast Generation: AI creates forecasts without manual inputs, using multi-level time series models.

Anomaly Detection: Detect sudden spikes, drops, or disruptions in demand to adjust plans dynamically.

Demand Sensing: Uses real-time data (POS, weather, promotions) to make short-term demand adjustments.

Causal Modeling: Identifies hidden drivers (e.g., social media buzz, competitor launches) impacting demand.

Promotion Planning: Forecasts uplift due to campaigns, discounts, or seasonal marketing events.

Retail: A global fashion brand reduced stockouts by 35% by using AI to correlate social media trends with in-store and eCommerce sales.

CPG (Consumer Packaged Goods): A major FMCG company used ML-based demand sensing to improve forecast accuracy by 42% during pandemic volatility.

Manufacturing: A heavy-equipment maker optimized spare parts inventory by combining predictive analytics with IoT data from deployed machines.

To harness the full potential of advanced analytics, organizations need seamless data integration across ERP, CRM, SCM, eCommerce, and third-party APIs. This is where platforms like eZintegrations™ offer a strategic advantage:

Unified Data Pipeline: Connects siloed systems and normalizes data formats (structured and unstructured).

API Marketplace: 1000+ ready APIs to ingest external data like weather, footfall, promotions, or supplier inputs.

AI-Ready Infrastructure: Enables platforms like Goldfinch AI to run ML models on real-time and historical datasets.

Visual Workflow: No-code drag-and-drop integrations to accelerate deployment without IT bottlenecks.

Combined with Goldfinch AI, eZintegrations™ supports intelligent demand planning by feeding the right data into ML algorithms that continuously learn and optimize.

Success with AI-based demand planning isn’t just about technology—it also requires people, processes, and strategy. Here are some tips to make your implementation successful:

Start with Clean, Integrated Data: Invest in data integration tools like eZintegrations™ to ensure high-quality, unified inputs.

Involve Cross-Functional Teams: Collaborate with sales, marketing, and finance to align on demand assumptions.

Pilot and Scale: Begin with one region or product line, then expand based on success.

Combine Short-Term and Long-Term Models: Use demand sensing for short-term agility and AI forecasts for strategic planning.

Invest in Explainable AI (XAI): Ensure transparency in models so business users trust and act on the forecasts.

The future of demand planning will be prescriptive, not just predictive. With the rise of generative AI, LLMs, and autonomous agents, systems will not only predict demand but also recommend actions across supply chains, procurement, and logistics.

Key emerging trends include:

Digital Twins for Supply Chains

GenAI Copilots for Forecasting Teams

Blockchain for Demand Traceability

Edge AI for Real-Time Store-Level Insights

eZintegrations™ and Goldfinch AI work together to make advanced demand planning not only possible—but scalable and actionable.

Here’s how they help:

Connects Disparate Data: Unifies ERP, CRM, sales, inventory, supplier, and third-party market data through visual no-code workflows.

Real-Time Syncing: Enables instant updates across systems to reflect the latest demand signals.

API Marketplace: 1000+ prebuilt APIs make it easy to ingest external data like weather, social chatter, economic indices, etc.

Data Normalization: Ensures clean, AI-ready inputs across structured and unstructured formats.

AI-Powered Forecasts: Runs ML models that learn from trends, seasonality, and causal factors for improved accuracy.

Unstructured Data Modeling: Leverages OCR, PDFs, emails, and reports to extract demand drivers often missed in structured data.

Demand Sensing & Simulation: Reacts in real-time to new signals and runs scenario modeling for risk-free decision-making.

Explainable AI: Offers transparency so planners understand what drives each forecast and build trust in automated insights.

From data ingestion to AI-driven decisions, the eZintegrations™ + Goldfinch AI stack delivers continuous, predictive, and agile demand planning.

Helps businesses move from reactive to proactive planning, especially in volatile markets or complex supply chains.

In a world where demand is dynamic and disruption is constant, advanced analytics offers the precision and agility needed for smarter decisions. Enterprises leveraging AI-driven demand planning can outperform competitors with faster response times, better customer service, and optimized inventory.

Platforms like eZintegrations™ and Goldfinch AI empower organizations to unify data, automate insights, and deliver intelligent demand forecasts at scale.

Ready to transform your demand planning strategy? Book a free demo of eZintegrations™ today and see the impact of AI-powered analytics firsthand.

1. What are advanced analytics in demand planning?

Advanced analytics applies AI, ML, and data modeling techniques to improve demand forecasting accuracy and supply chain responsiveness.

2. How is AI better than traditional forecasting methods?

AI continuously learns from historical and real-time data, adapts to market shifts, and handles complex variables that static models can’t.

3. What industries benefit most from advanced demand planning?

Retail, manufacturing, CPG, healthcare, and logistics any industry dealing with variable demand and inventory complexity.

4. Can advanced analytics reduce inventory costs?

Yes. By accurately predicting demand, businesses avoid overstocking or understocking, reducing holding and write-off costs.

5. How is real-time data integrated into demand forecasts?

Platforms like eZintegrations™ connect real-time data sources (POS, ERP, CRM, market APIs) into AI models that adjust forecasts instantly.

6. Do I need a data science team to get started?

Not necessarily. Tools like Goldfinch AI come with pre-trained models, and eZintegrations™ allows no-code integration workflows for fast onboarding.