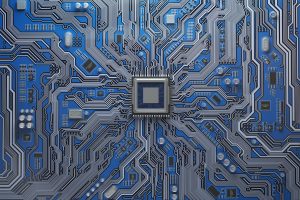

The semiconductor industry is experiencing transformative growth driven by several key trends. The expansion of IoT is increasing demand for advanced chips in smart devices. AI advancements necessitate AI-ready hardware, while the shift to EVs and autonomous driving requires sophisticated semiconductors. Additionally, the rollout of 5G technology is enhancing connectivity demands, driving innovation in semiconductor solutions.

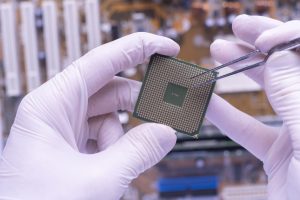

As technology nodes shrink, manufacturing processes become more intricate and expensive.

The compression of semiconductor devices necessitates meticulous quality control.

Demand fluctuations can impact profitability and customer satisfaction.

Companies must adapt to the rapidly evolving tech landscape. Emerging technologies like AI, IoT, and 5G are fueling demand for advanced chips.

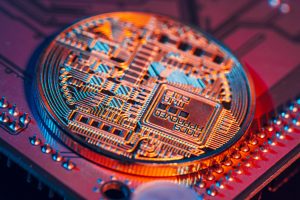

Incorporating tools like AI and automation to facilitate innovation and maintain a competitive edge is crucial.

The relentless pursuit of compression puts pressure on quality control, yield improvement, and time-to-market.

Coordinating with global suppliers adds logistical complexities. Managing cross-geography operations becomes challenging.

Global events like COVID-19 exposed vulnerabilities in the semiconductor supply chain, impacting production from raw materials to delivery.

The semiconductor industry is heavily influenced by geopolitical tensions, which can lead to trade restrictions and tariffs.

Relying on few suppliers for critical materials risks disruptions. Supply issues can cause major delays and raise costs.

Semiconductor companies face challenges in navigating global trade, environmental, and manufacturing regulations.

Manufacturers must adopt sustainable practices to meet tightening environmental regulations, focusing on waste reduction and eco-friendly processes.

Connect manufacturing systems, supply chain platforms, ERPs, quality systems, and partner applications to ensure real-time visibility across production and operations. Reduce data gaps, improve traceability, and support complex, high-volume processes with reliable, secure integrations.

Goldfinch AI extracts data from engineering documents, purchase orders, test reports, and supplier invoices and integrates it with manufacturing and ERP systems. Live dashboards deliver real-time visibility into production flow, supplier performance, and operational bottlenecks.